Having spent 2 years at Rochester Junior College in Rochester, MN and after landing a job at 3M company in St. Paul, MN as a "Radio-chemical technician", I was ready for the "Big Time"

Note to dear readers: This is a long post because a VW Beetle cannot be described in a few words!

Note to dear readers: This is a long post because a VW Beetle cannot be described in a few words!

Thus, at the age of 20 and with steady money coming in, I purchased a new 1962 Volkswagen Beetle at a VW dealership in Rochester, MN. It weighed 1570 lbs. and cost about $1 per pound ($1,600). It had a light alloy, 4 cylinder, 40 horsepower rear-mounted engine with a maximum speed of 72 mph (on level ground) and was supposed to get 32 mpg with a carburetor. It also had a nice 4 speed manual transmission, rear-wheel drive and air-cooled engine, independent suspension and telescopic shock absorbers and a 6V electrical system charged by a generator (with brushes). The battery was located under the rear seat cushion. Part of the "Beetle Package" was sun visors for driver and passenger!, coat hooks, an "automatic" windshield washer, overhead light and AM radio. There were no seat belts The car could hold 4 adults and had room for luggage in a compartment under the front hood and in a carpeted compartment behind the rear seat.

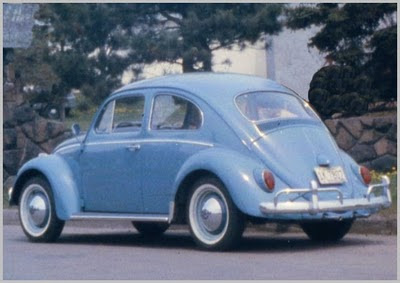

Below are two photos of Humble Blogger's 1962 VW Beetle and a third photo of Loving Wife Rose's 1957 VW convertible. The Beetle was a rage in the early 60's for young people. It was sporty and fun to drive. It was first a bewilderment then an amusement to our parents who weren't that many years away from fighting the Germans in WWII.

However, once children started to arrive, the Beetle quickly became over crowded! Our 1st born John rode in the little compartment behind the rear seat. In addition, the Beetle's other nuisances and deficiencies soon began to appear!

Humble Blogger's 1962 VW in a June 1963 photo. Color was "Gulf Blau"

Humble Blogger Tuning up the 1962 VW in the Back Yard in Autumn 1964

A Repair Manual Very Much Needed!!

Loving (2nd) wife Rose Standing by her 1957 VW Convertible in a 1967 photo

Humble Blogger was not to meet her for another 24 years!

Humble Blogger was not to meet her for another 24 years!

Where's the heat!: The salesman on the showroom floor promised that a fan-controlled, air-cooled engine (not water-cooled) would produce heat very quickly in winter as the engine didn't need to heat up a water/antifreeze mixture. I was to learn otherwise.

1. Turning on the heat inside the car was done by rotating a large knob. This manually closed two metal flaps diverting hot air (generated by the cooling fan blowing air over the hot running engine) from going outside onto the road beneath the car, into the passenger compartment. The volume of air flowing into the car was a function of engine RPM. When the engine idled or when the car was driven at in-town speeds of 30 mph, very little air volume came into the cabin. When travelling at 50 mph however, the air volume was much greater. These limitations worked fine until the outside temperature dropped to about 20F. At this temperature the heat went from hot to tepid. In Minnesota winters, when temperatures often dropped below 0 degrees F, there was little or no heat as the outside temperature was cooling the engine by itself!

2. So in winter, there was no way to effectively defrost the interior windshields and the other interior windows. One needed a scraper to remove the frost from the inside of the windshield just to see out! There was no hope of keeping the outside windshield clear as there was little heat to melt snow and/or ice. In order to see out the windshield during the first few miles of driving, until the engine produced some heat to defrost a small see-through window, the driver needed to both scrape the inside of the windshield, open the driver's side window and reach outside to scrape the outside windshield! (Yes it was possible to be in the car and reach to scrape the driver's side of the windshield).

In chatting with the VW salesman about this problem, he suggested keeping a vent window open a crack on the driver's side to keep the air moving. This would help defrost the windows. That it did, but it didn't make sense to let in more cold air into the passenger compartment when the inside was already so cold!

3. I first resolved some of the heating and defrosting problem by installing an after-market blower in the driver's side heat channel. This connected to the 6V electrical system and was operated by a switch installed in the dash. Thus at idle speeds when air volume was low, the blower would keep a more constant air flow for heat and for defrosting the driver's side windshield.

4. The second, more expensive (and dangerous!) solution was to install a "gas heater" under the hood of the car. This was done by a professional and included a copper tube hookup to the gas tank (which was located where a radiator would be in a "normal" car). I believe it was also hooked into the car's electrical system. From inside the car one turned a knob which would start gas flow and ignite the gas heater. Soon wonderful hot air would begin to flow into the cabin warming its freezing passengers. The combustion gasses exited through a flexible pipe through a drilled hole in the wheel well. If the heater exhaust pipe in the wheel well got plugged with snow in winter time, the gasses would backup into the passenger compartment!! One had to act quickly to turn off the heater and unplug the snow from the pipe. These heaters occasionally exploded, damaging the front hood and sometimes the passengers. But heat alone, still did not defrost the windows which collected the humid air breathed out by the car's occupants.

5. The car had little or no heat in the winter, because the 40 hp engine simply didn't produce enough heat to counter the cold. Therefore it didn't get the motor oil hot enough to burn away water formed during fuel combustion which condensed into the motor oil. The oil level on the dipstick would actually rise during cold weather and the oil would take on a yellow-cloudy appearance due to emulsified water. It was very important at that point to change oil as the water-contaminated oil was not a good engine lubricant!

6. The 1962 VW often didn't start in Winter. There was no garage for the car, so I built a carrying case to hold the 6 volt battery. During the very cold Minnesota winter nights, I lifted the rear seat cushion (easy to do), disconnected the battery terminals, and carried the battery into the house for the night. In the morning I re installed the battery and had a better chance of turning over a very stiff engine. This didn't always guarantee that the car would start but it helped.

"Automatic" windshield washer: The Beetle's windshield washer was inexpensive and innovative involving no electrical pumps. It consisted of a white plastic 1 or 2 liter plastic container (washer unit) inside the hood of the car (remember this is where the luggage compartment was because the engine was in the rear). One unscrewed a cap, filled the container with washer fluid and screwed the cap back on tightly. Near the cap, protruding through the body of the container, was a tire valve stem. The stem stuck out about 3/4 inch. One needed to attach the provided tire pump to the valve stem and pump in a certain amount of pressure. Then, while driving, when the washer was needed, simply pushing a button on the dash, opened a valve allowing pressurize washer fluid to flood the windshield. However, too soon, the fluid and/or the pressure diminished to the point where there was no more washing the windshield. Often the pressure was gone long before the fluid.

I eventually became innovative myself. I removed the interior valve device from the valve stem and force-fitted a 1/4 in. or 3/8 in. (inside diameter) piece of yellow rubber latex tubing over the protruding valve stem. I directed the other end of the tubing into the passenger compartment just under the dash and within reach. I attached to this end of the tubing a black rubber bulb having a one-way valve. Squeezing the bulb put air pressure into the washer unit. Releasing the bulb allowed the bulb fill with air again via the one-way valve while maintaining pressure in the washer unit. Continued squeezing and release of the bulb quickly built up enough pressure to allow the windshield to be cleaned. That is until the washer unit became empty of fluid.

Rust, Rust and more Rust: I'm sure the VW Beetle survived much better in the warmer, drier climates than in the snow belt! In Minnesota the Beetle was exposed to rain, ice, snow and road salt. Regular use of WD-40 rust penetrate and lubricant was a necessity!. The rust caused the hinges to rust so that the doors were very hard to close; caused the muffler to rust and need replacement; caused the running boards and bumpers to fall off; caused the floor pedals, where salt accumulated via a snow laden shoe, to rust; caused the metal flap hinges which diverted warm air into the passenger compartment to freeze open (or closed); caused the bottom of the car to rust to the degree that holes formed and one could see the road beneath the foot pedals (where salt had accumulated). The solution was to place a piece of 1/4 in. plywood over the hole area. Even so, highway water often splashed up onto the floor of the passenger compartment as I was driving myself three other guys in our car pool to work in the morning.

Most annoying was the effect the rust had on the speedometer /odometer. One end of a flexible metal sheath containing a cable was screwed onto a fitting on the back of the speedometer. The other end of the sheath/cable was screwed onto a fitting on the drive shaft of the car. As the drive shaft rotated, the cable within the metal sheath would also rotate. The speed of rotation of the cable turned gears inside the speedometer which was calibrated to convert drive shaft rotations into mph (and kmh). When rust attacked the sheath and cable, the cable would at first begin to whine because of the increased resistance inside the metal sheath. The noise was awful! Then suddenly, the cable snapped, breaking inside the sheath, and the speedometer stopped measuring speed and miles driven. The only solution was to have the cable replaced, which was easy but a nuisance. Or to drive the car the way it was and try to guess at the speed.

Loving wife Rose told me the story of driving her 1957 Beetle to pick up her sister Maxine from work one wintry evening. Maxine was riding in the back seat and complained that the seat was getting warm and was smoking! Rose stopped the car and lifted the rear seat cushion (where the battery resided) and saw that it had fallen through the rusted floor and was dragging on the pavement below! Connections were shorting out causing sparks which ignited the seat cushion material and caused the smoke and the heat. They were able to easily put out the fire. The next day she "fixed" the problem by placing a (you guessed it) a 1/4 in. piece of plywood over the hole. Her sister however didn't ask for a ride home any more.

When Rose bought her VW the speedometer didn't work (for the reasons described above) but she never fixed it.

Another time, she was driving her Beetle down University Avenue and the rear bumper fell off. When her passenger wondered aloud if she was going to stop to retrieve it, Rose responded "No, I'm to embarrassed." Also if you study the photo carefully, you will see that the running board had already rusted and fallen off on the passenger side shown. She had her VW convertible about 1-1/2 years until someone dumped sand in the gas tank giving to it an inglorious end!

Unpredictable, Odd Behavior and Other Stories: The beetle had rear-wheel drive and the engine was just above the rear wheels. This made summer driving easy. The weight distribution between the rear and front wheels was such however that on ice, the car was unpredictable.

1. On two occasions, I was driving down a city street on ice/snow and the car suddenly rotated 180 degrees so that the nose of the car was facing the direction it had come from!! It happened in an instant, probably after applying the gas pedal. Fortunately no other cars were near by to crash into.

2. Another time, I parked in a snow-covered parking lot of St. John the Evangelist Catholic Church in Little Canada, MN to attend Sunday Mass. After church, my Beetle was stuck in the snow. Since the car was easy for one person to push, I put the transmission into low gear and released the clutch allowing the rear wheels of the stationary car to spin in the snow. I then got out of the car, walked behind it, and pushed it out of rut. The car slowly began to move forward gradually picking up speed. I, suddenly realizing the stupid thing I had just done, ran after the moving car and was able to get into the driver's seat and regain control before it hit anything!

3. Since the car was easy to push, when it didn't start (which was often especially in winter with a challenged 6V system with no alternator, only a generator), it was easy to get it moving to "pop the clutch". If there was a passenger, he or she could get out and push the car while the driver popped the clutch. If there was no passenger, the driver could put the car into neutral, open the driver's side door, get out of the car and stand between the open door and car and push forward to get it moving. Once the car was rolling, the driver jumped back into the car, depressed the clutch, shifted from neutral to low gear and released the clutch to engage gears, which got the crankshaft rotating and moved the pistons up and down and thus start the car.

4. A skilled driver could listen to the engine rpm and shift gears without depressing the clutch at all! This was especially true when the clutch began to wear.

5. The car was always needing shock absorbers, "valve job", new clutch plate, rebuilt or new starting motor, rebuilt or new generator, muffler, tune-up job and even a rebuilt engine which could be replaced in one day. For major work, I took my 1962 VW to "Willie's Import Auto Repair" located near the University of Minnesota. This was convenient when I was attending the University. Willie had a German accent and likely immigrated from Germany. He a true professional. He was to a VW what a surgeon was to a patient. Willie could press both palms on the two exhaust pipes of a running VW, feel the pressure and diagnose whether the car needed a valve job! When he worked on a VW he first laid a towel on the concrete floor then arranged the metric tools he would be needing on the towel in numerical order. More than once, he saved my VW.

6. I believe the year was about 1970 (the VW was 8 years old). I and the family were driving the 60 miles from St. Paul, MN to Rochester to visit parents when suddenly the car stopped and the passenger compartment filled with smoke! This was the end. Something bad had happened to the engine. A common "coup de grâce" I was to learn afterwards. There was no use getting a new engine as the rest of the car was too rusty to salvage.

The next family car was a Dodge Dart with a "straight six" 6 cylinder engine. It had a lot more room and a heater!